Page 22 - TEKNOCONVEY GENERAL PRODUCT CATALOG

P. 22

http://www.teknoconvey.com/en

Lab & Pilot Applications:

PerMix is able to offer lab - pilot size ploughshare mixers for research & development purpose.

The small size machine is very helpful for customers when the ingredients for R&D are

expensive, and to meet the badget limit at the first stage. With the good performance of the lab

& pilot mixer, it is easy to scale up for a medium size or even bigger one.

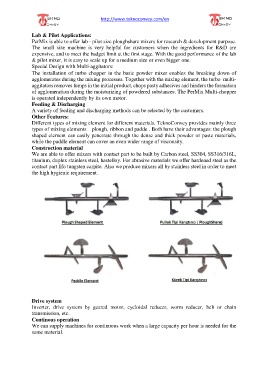

Special Design with Multi-aggitators:

The installation of turbo chopper in the basic powder mixer enables the breaking down of

agglomerates during the mixing processes. Together with the mixing element, the turbo multi-

aggitators removes lumps in the initial product, chops pasty adhesives and hinders the formation

of agglomeration during the moisturizing of powdered substances. The PerMix Multi-chopper

is operated independently by its own motor.

Feeding & Discharging

A variety of feeding and discharging methods can be selected by the customers.

Other Features:

Different types of mixing element for different materials. TeknoConvey provides mainly three

types of mixing elements – plough, ribbon and padde . Both have their advantages: the plough

shaped element can easily penetrate through the dense and thick powder or paste materials,

while the paddle element can cover an even wider range of viscousity.

Construction material

We are able to offer mixers with contact part to be built by Carbon steel, SS304, SS316/316L,

titanium, duplex stainless steel, hastelloy. For abrasive materials we offer hardened steel as the

contact part lifo tungsten carpite. Also we produce mixers all by stainless steel in order to meet

the high hygienic requirement.

Drive system

Inverter, drive system by geared motor, cycloidal reducer, worm reducer, belt or chain

transmission, etc.

Continous operation

We can supply machines for continuous work when a large capacity per hour is needed for the

same material.