FOR DETAILED VACUUM CONVEYING ARTICLE = http://www.teknoconvey.com/sayfa/vacuum-conveying-systems/

Vacuum conveyors small portable units for minor and macro ingredient unload or transfer, to large units capable of moving up to 7.000 kg/hr of material and suitable for transport in big bag unloading, dosing, and batch or party feeding of process tanks, mixers hopper, sieving machine , and other dry powder and granular process equipment.

Basic principle of vacuum conveying is to move the powder and granular material in a relatively uniform stream from a feed or supply source to a delivery point. The application of air, supplied via a multiejector vacuum pump or by vacuum blower, creates a high enough air velocity and low enough solids to air ratio to effectively move the materials.

Our vacuum conveyors are engineered with best features designed to make them easy to instal, luse, and maintain. Our top door access panel not only provides a tool-less entry and filter change, but also allows for installation in tight spaces, even near the ceiling.

Using the exclusive top door you can easily access the dust filter for inspection or changeover. Less Energy Consumption – no need noisy blower.

Vacuum is used with great advantage in conveying dry powder products through dedicated pipe systems. TeknoConvey vacuum conveying systems are built of high quality material. When producing food, pharmaceuticals and chemical products there are demands on the highest possible degree of safety as to hygiene and operation. TeknoConvey vacuum conveyors have been developed as an answer to the severe requirements of operational safety and hygiene in the food, pharmaceutical and chemical industries. All our vacuum conveyors are available with either an multi ejector driven TeknoConvey vacuum pump or with a mechanical pump.

Vacuum Conveying is the process of moving bulk dry materials, such as powders, from place to place within a plant using suction. The material is transferred in a tubing from the pick up point or source to the customers process. Most Vacuum Conveying System transfer product based on a timed interval to the vacuum receiver. At the end of the timed sequence the discharge valve can open and the material conveyed can discharge in to the process.

Dense Phase Vacuum Conveying the material is transferred in slugs within the convey tubing. The material moves slower then dliute phase conveying and is excellent choice for friable product or a blend of powders and granul.

Dilute Phase Conveying the material is entrained in the air stream and the is an almost equal part of air and product. This method is excellent for conveying almost any type of powder like suga, starch, black carbon or flour.

TecnoConvey is expert at moving bulk solids. Just as it is not necessary to become an expert on how to build a vehicle when purchasing one, it is also not necessary for users of pneumatic conveyors to become experts at vacuum conveying to incorporate them into their processing line. While it is a good idea to have a broad understanding of how pneumatic conveying systems work, no pneumatic conveyor manufacturer will ever ask a customer if they need a dense phase or a dilute phase system. There are, however, many other questions a conveyor manufacturer will ask about a process, and the materials used in that process, that will aid them in designing a system with the necessary components to provide a solution that integrates into a customer’s process.

· Pick Up Point

· Process Equipment

· Plant Site and Industry Environment

· Material Bulk Density

· Conveying Distance

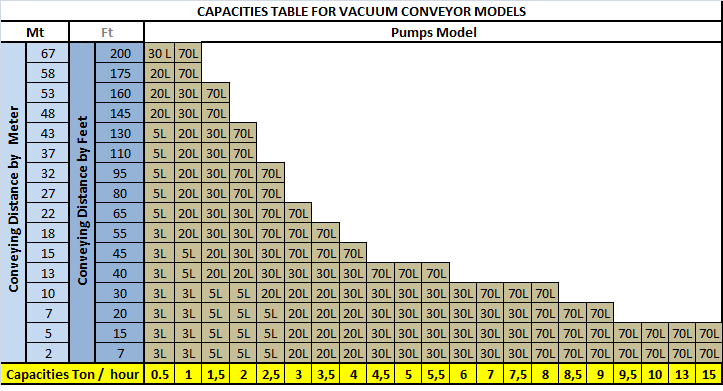

· Conveying Rate

· Batch vs. Continuous Conveying

· Material Characterisitcs

· Dust Free Transfer of Powder

· Easy to Clean.

· Small Foot Print

· Efficient conveying method of powders and granules

· Easy to install

· Low Power Consumption.

· Multistage vacuum ejectorsystem no moving parts

Instead of the standard material discharge valve, TeknoConvey can be equipped with material collectors in various sizes and with additional functions.

Vacuum Conveyor as an automized material feeding system: Convey and feed powders and mixtures directly into filling machines, tablet presses etc. Min- and Max-level sensors prevent overfilling and keep processes stable.

TeknoConvey diverter valves connect one vacuum conveyor to a number of material loading stations or other systems. By this way, a single vacuum conveyor picks up different or the same materials from silos, big-bags, valve or open mouyh bag dump stations, buckets, tanks or from drums through a suction line.

In addition to the standard pneumatic controls for the basic functionality of the vacuum conveyor, there are numerous enhancement and modification options

Our in-house pneumatic and PLC control engineering experts take care, that all requirements and specific demands are fulfilled.

“Wetting/Washing in Place“ (WIP) and “Cleaning in Place“ (CIP) operations require very smooth surfaces with only few connections, free of gaps. Hygenic design is major to modularity.

For many years, modified PPC Vacuum Conveyors are in operation, in which, after the powder transport all product contacting surfaces are rinsed without dismantling of the vacuum conveyor. Due to the optimized design and the installation hygienic valves all components and surfaces are wetted effectively. After rinsing and flooding, the washing liquid is fully drained. Upon request, the filter may be replaced by a flushing cover and the remaining separator then is CIP cleaned.

A “full” CIP solution is available, too. During rinsing, cleaning and drying the filter remains inside the vacuum conveying system. These come with specific spraying and washing nozzles with rinsing/spray outlet in different directions, have no pocket areas and unique sanitary drain valves for the filter and separator.

If the vacuum conveyor itself is installed inside aggressive atmosphere or comes in contact with aggressive media, the outside of the conveyor will be coated, too. Additionally, Multijector Vacuum Pumps are available in various materials (such as stainless steel) and can be supplied acid-proof.

The basic advantages of compressed air driven vacuum pumps are well known: small size, low weight, simple design, little maintenance and wear resisting operation put them in first place when it comes to pick-and-place applications. The easy installation, control and free positioning make work easy with their quiet operation and neither heat nor oil mist emission.

Classical Venturi comes with a primary nozzle (injector), a secondary nozzle (diffuser) and a jet chamber (the gap between). The compressed air rushes through the primary nozzle, expands and accelerates, which causes a pressure drop. On its way towards the secondary and third nozzle it catches and mixes surrounding air and finally exits the Venturi through the third nozzle.

Energy consumption only in the suction cycle

In a vacuum conveyor the multi stage ejector pump is turned on only during the suction cycle. While discharging the separator, the Multijector can easily be switched off. It requires no starting time for the next cycle like electrical pumps, also it has no wear during start and stop. Our ejector saves about 1/3 of compressed air during discharging, while electrical pumps need to run continuously and require additional vacuum valves to shut off the vacuum conveyor during discharging.

Some conveying duty bring up the question: How much material did the system convey and feed?

Our Multi Stage Pump Vacuum Conveying and Weighing/Dosing systems measure both the incoming and outgoing material flow. You can set systems to convey a certain amount or just control the feed rate over time.

Vacuum Conveying systems with weighing and dosing function are built on the basis of weighing hopper, thereby providing a wide range possible applications. They work gravimetrically with the vacuum conveyor mounted on a special frame completely isolated from external forces and loads. The filling weight is constantly measured throughout the suction cycle.

The amount of material to be conveyed is specified (touch screen input). If different materials have to be picked up from a number of sending stations, the control switches the valves to activate the proper transportation line automatically. Conweigh systems are able to set up recipes.

The combined transfer/weighing Conweigh system is used for dosing weights of 2,3 kg and above. Typical for vacuum conveying, the transported material is released discontinuously in cycles. The maximum dosing capacity is defined by the transportation capacity of the vacuum conveyor.